How to enhance CNC drilling machine parts manufacturing speed?

What is better CNC Router or Machining Center?

To be able to choose the ideal machine for your company and understand what its needs are? It is necessary to understand the differences between CNC Router and Machining Center. The choice of CNC drilling machine parts is easy to make correctly and wisely.

Choosing tools and alternatives will help in the increase and quality of your production. It reduces possible waste is important. And, for this to be possible, it is important to look for technologies that can meet your expectations.

Characteristics and differences between CNC Router and Machining Center

CNC Router

This machine comes on a metallic structure, where several axes move by screws. It works through a motor. It helps in the execution of 2D cutting and engraving jobs. Moreover, they are great for woodworking and furniture production. It is an important machine having CNC drilling machine parts for those who need to make all kinds of cuts in thicker materials.

In addition, it works with cutting various types of material, such as MDF, PVC, ACM, acrylic, among others. This equipment is able to automate several steps in a very precise and standardized way, reducing process time and speeding up production. Generally common to make wood productions, the Router machine contains components that help in this process.

What is the use of cutting table?

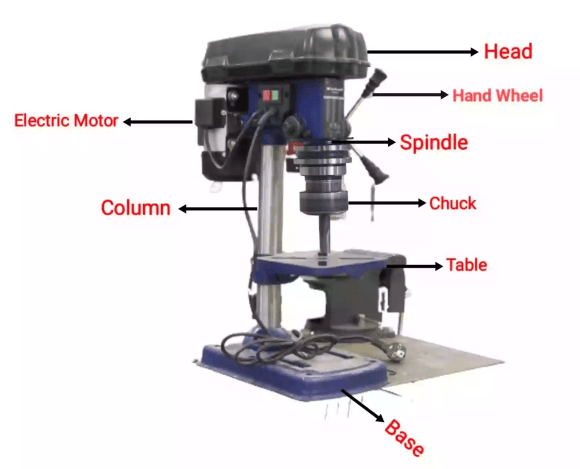

For example, as it is a CNC drilling machine parts, it has software for the development of the design and a computer that commands it to be complete with great precision. Spindle makes the cut and the design that the wood must contain, using the computer commands. Another important part of the Router is the cutting table, designed to support the part being cut, in addition to protecting it.

There are several types of table for every need, so the ideal is to choose one that will meet your demand quickly and efficiently. It is a machine aimed at drawings that require a lot of details, made mainly in wood. With it, it is possible to produce furniture and make precise cuts, avoiding possible waste in production.

Machining center

This CNC drilling machine parts, as well as the Router, also uses a computer and software to apply its commands. But there are some differences between the two. This machine is common to produce and model parts. She can perform these functions without having to stop to change or change the tools common to get the job done.

So, in addition to having an accelerated production time, this equipment is able to produce a large number of parts. It comes with exact and customized diameters. Moreover, it standardizes the batch in a qualitative and very uniform manner. In other words, the machine optimizes the production of parts, further improving the quality of the product offered.

Among the main operations carried out by the Machining Center are:

Turning: based on the movement the CNC drilling machine parts make on its own axis, commonly common for the manufacture of cylindrical parts;

Drilling: it is an operation that the machine performs to finish holes or to further widen the holes in the part;

Planning: In which the equipment aims to obtain flat parts;

Broaching: It removes material from the surface of a piece. It happens in a way that leaves it according to the command in a progressive way.

Milling: is a process common to create gears. These operations aim at companies and industries that manufacture parts with the mechanical wear process.

Use of CNC drilling machine

Present in several industries, whether automotive, naval, household appliances or electronics, machining is important. It is to standardize and leave CNC drilling machine parts with the correct specifications and dimensions.

So that they are common properly. Unlike the Router machine, which generally uses wood as a raw material, the machining center uses materials such as: aluminum.

There are many differences between machines. But their main function is to shape an object or part in a standardized way. It is to give command of the execution and creation of the product itself. Each of these pieces of equipment is geared towards specific goals and it’s up to you to define the best machine for your company or industry!

What to take into consideration?

Below are the main points to consider when choosing a CNC router.

Desktop

The first requirement for the worktable is that it must be stable. This is because its stability will directly affect the CNC drilling machine parts’ precision and quality. Therefore, the base of the CNC router must be firm and not deformed, otherwise it will oscillate and consequently the head will not follow the programmed path, directly affecting the processing quality.

Motor

The motor directly affects the production speed of the CNC router machine, and as we know, in this case speed equals efficiency. Therefore, its speed will affect the processing efficiency and consequently the economic benefits. In industry there are mainly two types of steering motors, servo motor and stepper motor. The former has the advantages of high precision, fast speed and long service life.

Lubrication system in CNC drilling machine parts

CNC drilling machine parts lubrication system can prolong machine life, in addition to improving machining accuracy and also increasing production efficiency. Thus, the system can be automatic and manual lubrication. So, for equipment with little lubrication points and relatively dispersed, the most suitable is the first option. For equipment that operators can easily access, manual lubrication is a choice.

Support

An issue overlooked by many when buying a CNC router machine and any other products is the support offered by the company. It is very common to see companies on the market that sell CNC routers, but do not provide the necessary service, often not including their own detailed manual. So, when choosing your CNC router, in addition to the model, also check if the company will help you later.

Budget in CNC drilling machine parts

After verifying the operation of the CNC drilling machine itself and CNC drilling machine parts, it is important to understand its availability for purchase. To do this, estimate the cost of purchase, cost of use, maintenance and subsequent repairs according to your production requirements. Very high purchase costs will increase the company’s financial burden.

Summary CNC drilling machine parts

A very low purchase cost may not achieve the expected processing effect, thus resulting in the waste of labor, material and financial resources, also affecting the normal progress of production. So have a focus and know what to work with.